Palu - Agriculture (Wheat)

This part of the agriculture sub-heading concerns the successive phases of wheat cultivation, from sowing to harvest until winnowing and the preparation of bulghur in Palu.

Sowing and reaping

The villager begins to plough the field earmarked for wheat four or five times in the spring and summer seasons, allowing a 10-15 day rest between each ploughing. Then in the middle of September, the irrigation of the fields begins. Only after the soil has been well dampened, or as the peasant would say ‘be damped’, will he start to sow the grain. After this has been completed, the field is ploughed again, to bury the grains beneath the soil. Then follows the harrowing, thanks to which the wide furrows are closed up, the soil is levelled and individual grains still left on the surface are buried.

Thus ends the first phase of wheat cultivation. The peasant returns to the field once in April or May when, after the snows have melted, green shoots of grain are showing above the ground. [1] If there is no drought or hail, the peasant doesn’t have anything special to do with the wheat field; this state lasts until June, in other words until harvest time. In reality the wheat field doesn’t even need weeding. The harvest, or as the peasants say, ‘the gathering’, occupies them during the months of June, July and August. This is a collective enterprise; the whole village determines the first day of harvesting, all become aware of it, bring out their tools and prepare for that day. It also happens that the village kizir (the bey’s representative in the village) stands on a high roof in the village on the evening before the first day of harvest and declares, in a loud voice, ‘Tomorrow the sickle... The sickle, yes..! Let there be a thousand of you to go to the field..! Don’t say you haven’t heard..!’ [2]

The reapers, with their sickles on their shoulders, arrive near the fields before dawn. The whole village has been mobilised. Only the old, housewives and children below the age of 6 or 7 remain in the houses. Babies that are still being suckled are taken to the fields too. Those who aren’t farmers or don’t have fields are also present and are paid for working for those families that don’t have even a few people to join in. Their daily wage is generally between 7 and 9 kilos of wheat. In some villages the harvest may take up to 80 days, thus if a peasant works for a wage through all this time, he could amass 560 kg of wheat. [3]

Each group stands together in the field in straight lines. Every reaper encases the five fingers of his left hand with protective coverings, and holds his sickle in his right. They are ready to reap, or as they say in local dialect, ‘to sickle’, but wait for the group leader’s (ondji’s) order. The group leader is the most experienced among the group, it is he that is notable for his swift sickle strokes and throughout the harvest directs the villagers alongside him. It is he too who divides the field into ‘ons’ or, in other words, equal areas to be reaped, which must be worked on collectively. Then he crosses himself and says, ‘In the name of the Father, the Son and the Holy Ghost, Amen...’ and puts a handful of wheat against the sickle blade – this is the signal. The sickles begin to strike the stalks of wheat. The reaping begins from the centre of the field, where the sheaves are also gathered. While these group and harmonious movements are being made, the leader’s voice may be heard, ‘Each reaper has to make what he reaps into a sheaf.’ In fact, work has its rules, as each reaper has to make 100-120 sheaves a day in the area assigned to them. [4] Each sheaf is secured with a gem or cord. These are prepared by the village women who first pull up, by the roots, a sheaf of stalks and keep them for a whole day in a fountain or basin. The stalks absorb water and become pliable and elastic. Then 10 of these stalks are knotted together, thus making a cord about two metres (6 feet) long.

After reaping two ons, the group sits down to breakfast, which is known as serdategh (literally ‘heart’s medicine’). This takes place between 7 and 8 in the morning. Work resumes and two more ons are reaped. The group then has half an hour’s rest. The centre of the field has already become a stubble field (khozan). The sheaves are stacked in ricks of about 5-6 metres (16-20 feet) diameter that, in the end, will conical stacks between 6-7 metres (20-24 feet) high. It is the time when the sun’s rays are hottest and the reapers are sweaty and tired, but they take up their sickles once more. The reapers’ strength has to be conserved, so the size of the ons to be reaped during these hours is reduced. Work stops at midday. The reapers gather in the shade of the tall ricks or the shelters (chatma) they have built using tripods. The housewives have already brought the hearty midday meal from the village, in which cracked wheat patties, broiled meat, yogurt-and-water drink (tan), yogurt soup, cream, butter and omelettes is to be found. After eating, they sleep for about two hours. The leader then gives the order to resume work. They reap 4-5 ons more until sunset. It also happens that during harvest time gypsies visit the fields, entertaining the reapers with drums and pipes, at the same time begging for sheaves of wheat. [5]

By the end of August all the wheat fields become white stubble fields, where only a form of weed called pozgeg grows, which is a harmless plant with only about a month or two’s life. It then dries out, its greenness changes to black and it becomes very combustible. After the harvest the peasant set fire to this plant, burning with it other noxious weeds and thorns. The dust of the burnt plants acts as a sort of fertiliser for the soil. [6]

The threshing floor

The villagers return home after the harvest. Their rest period lasts only a few days as threshing begins very soon afterwards. In the first instance the villagers have to remove the clod-like geshkurs made from dried animal dung covering the surface of the threshing field, previously coated on by them to protect the ground. Each member of the family carries several loads of geshkur home. They then irrigate the threshing floor and plough and harrow it until it is level and free from any plant whatsoever. They then leave it for a day or two, during which the ground dries and gets hard. Then the logh begins. This is the work of finally flattening the ground using a stone roller which is used over the entire area. This is done three or four times. In this way the threshing floor is not only smoothed but also completely hardened, like stone. This is of the greatest importance, bearing in mind that over the coming weeks, many people and animals will pass over it during the whole time that threshing continues. The ground must maintain its hardness or the threshed and winnowed corn will be mixed with stones and soil. [7]

The threshing floor is ready in this state; the villagers first move the peas, lentils, barley, linseed and beans that have been harvested here. Only about two weeks after threshing and winnowing these crops is the threshing floor given over to dealing with the wheat, which is the villagers’ main summer occupation. It can happen that the threshing floor is prepared in the wheat field itself, on the stubble. This can be seen more often when the amount of grain harvested in the field is limited. But generally speaking the threshing floor is located near the villagers’ houses. It is to this place that the villager brings the wheat and barley using carts or horses. They name this work as oran grel which can last as long as a week or two. [8]

The Palu cart

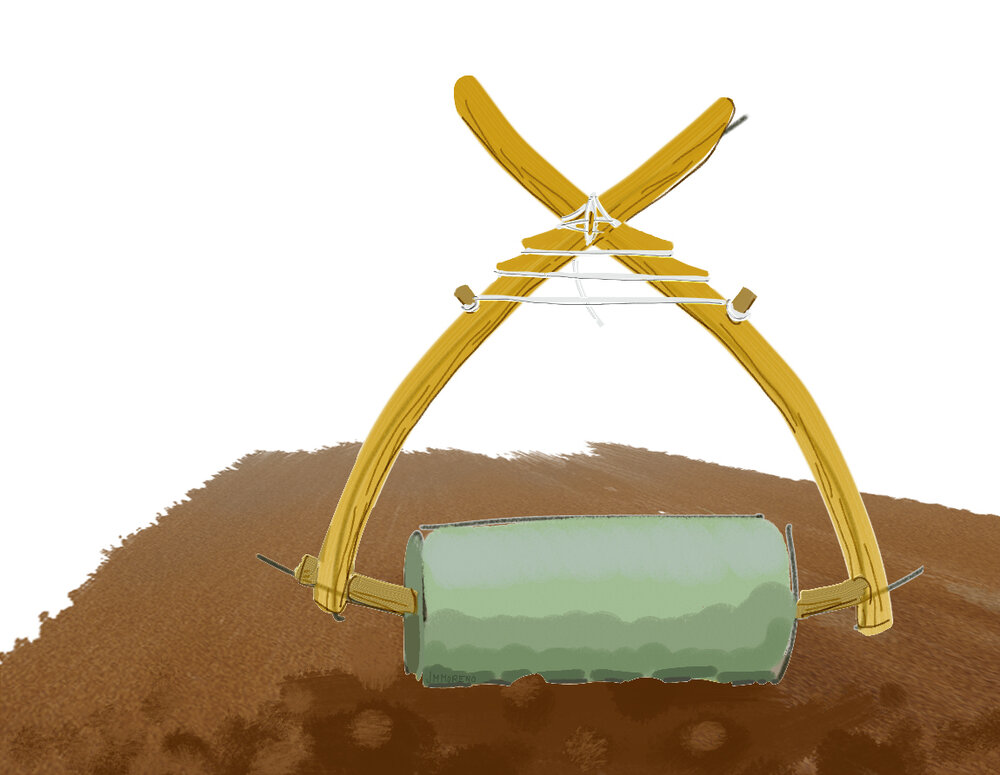

The villagers give this form of transport the name sal, meaning flat stone, as used in the paving of a surface. The cart is made up of the following parts: two areghs (stretchers), two kelans (rollers or wheels), a shaft, and a dun (load carrying area). The areghs or stretchers are two 3 to 3.5 metre (10 feet) long, 15-20 cm (6 to 8 inches) wide pieces of timber that have been stripped of bark. They are lashed together at one end, making the apex of a triangle that is secured using an iron ring (anur). The point at which the two stretchers are joined together is known as the ‘cart head’. There is a space of about 1.75 metres (5 feet) at the opposite end. Another two beams, the first 2 metres (6 feet 6 inches) long, the second about 1 metre (3 feet 3 inches) in length are attached to the stretchers, thus making them immovable and even more secure. These two new beams are fixed about 1.5 metres (4 feet) apart and the space filled with timbers set parallel to each other. This part of the cart is called the dun or load carrying area and the transportable items are loaded onto it.

The arghans (agra) (teeth) are 30-35 cm (approximately 12-15 inches) long posts that are secured (vertically) firmly opposite each other and centrally below the carrying part or dun.

The ned (shaft). The function of the ‘teeth’ is to keep the shaft secure. The latter is a beam about 2.5 metres (approximately 8 feet) long, whose two ends are fixed firmly in two square holes, one in each of the teeth and opposite each other. It is important that the shaft is made of hardwood. That is why mulberry wood is chosen in Palu.

The kelans (rollers or wheels). The shaft extends outside of the ‘teeth’ by 10-15 cm (4 to 6 inches). These ends are fitted with two wooden rollers or wheels. They are usually made of pieces of cedar or cypress wood and are secured in an iron rim. They are about 1 metre (3 feet 3 inches) in diameter. This roller-like wheel is not just one solid piece. It is made up of various pieces of timber joined and nailed together making them into a circular shape. It is an old tradition that the rollers (or wheels) in Palu are generally brought in from Geremeg village. A roller-like wheel can last for over a hundred years.

The four corners of the carrying part (the dun) each have a one metre (about 3 feet 3 inches) vertical post secured in them. The two on the right are joined together by horizontal rods, and the same arrangement is made on the left. This assists in the loading of the cart. The front and rear ends remain open. The cart with two wheels usually rests on its ‘head’. When it has to be held in a horizontal position, then a support about one metre (about 3 feet 3 inches) long is used under the ‘head’, which in Palu is called the kelkhede. On the left bank of the river in the district the villagers call this item dark. [9]

The threshing

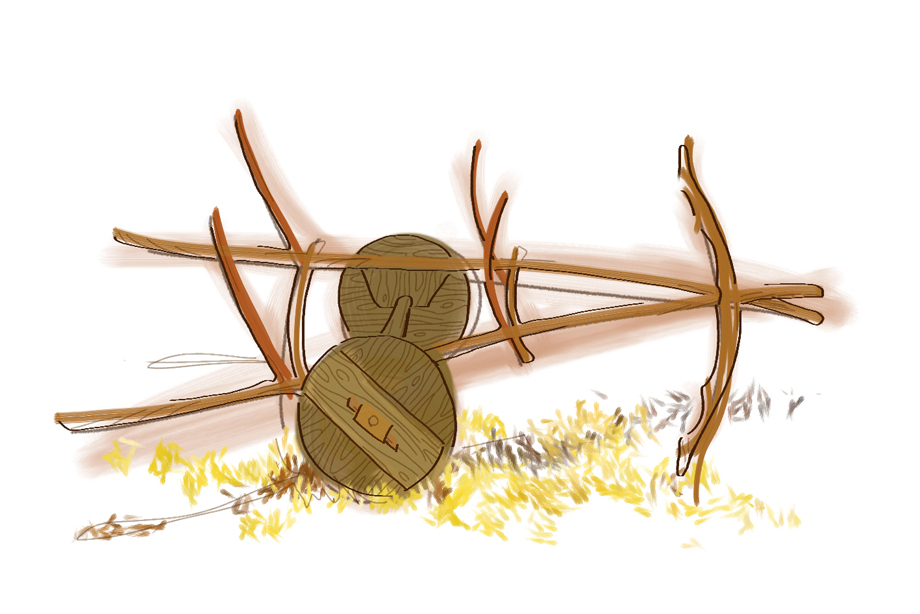

The sheaves of wheat are already stacked near the threshing floor and it is now possible to begin the actual work of threshing it; this might take two to three months. Through threshing the collected sheaves of wheat are turned into small pieces that become chaff, and the wheat grains are extracted from their shells and winnowed. To do this, a gam or harrow specifically made for the purpose is used. It is made of two pine planks each about 170cm (about 5 feet) long and 50 cm (1 foot 8 inches) wide, 4 to 5 cm (about 1.5 inches) thick. One end of each of the planks turns upwards, making a distinct curve. The two planks are fixed together with two pieces of wood or ‘belts’, about 1 metre (3 feet 3 inches) apart. The upper surface is known as the back of the harrow. The other surface, or bottom, is set with sharp flints. Finally the curved end of the harrow is called the ‘head’. There is, at the centre of the wooden ‘belt’ nearest the head, an opening through which a rope is passed which secures the harrow to a long hooked rod. This in its turn is fixed to the yoke rope, thus harnessing the harrow. The rope is known as a gamende and is between one and two metres (3 feet 3 inches to 6 feet 6 inches) long. [10]

The first stage of threshing is called charch. The sheaves of wheat are laid out in a circle on the threshing floor with the ears always towards the centre. The securing rope on each (the gem) is released and 200-300 sheaves are thus arranged. The villagers use wooden pitchforks (hoseli) to spread the wheat to be threshed (tsandz) evenly. This operation is called charchel. The thickness of the stalks and ears to be threshed the first time is about 75 cm (about 2 feet 6 inches). Then threshers begin their work. It is only with great difficulty that the yoked animals and the harrows they pull are able to ascend the wheat arranged during the charch. At the beginning the buffaloes or oxen are up to their stomachs in the wheat. The thresher villagers have them move in a large circle. This continues for 4 to 5 hours, until the thickness of the spread wheat has been reduced to the lowest possible. After this first harrowing, they keep the animals and harrows in the same circle and lay more wheat, to the thickness of 1 metre (3 feet 3 inches). The harrowing of each subsequent layer or charch lasts for about two days. In the case of great harvests where there is much wheat to be dealt with, up to six harrows might be used simultaneously. The inhabitants in the villages on the left bank of the East Euphrates (Murat, or Aradzani) river have the custom releasing all their draught animals on to the spread wheat before harrowing, and thus by treading it, considerably reduce its thickness. [11]

Winnowing

The mixture of wheat and chaff is collected in one corner of the threshing floor and made into piles, about 1.5 metres (4 feet 6 inches) high and 3-4 metres (10-14 feet) long. This collection operation is called teghel. It is important that the piles are arranged in a west to east direction, bearing in mind that during the winnowing – the next stage – the villager can take advantage of the wind blowing from the west during the summer months. The piles can remain in situ for days, until the arrival of the government official (the shahna) who determines the 10% tithe. [12]

The Palu villagers have two ways of winnowing. The first is using the wind. The thresher climbs to the top of a pile and, when the wind begins to blow, throws a forkful of the wheat and chaff mixture (malaghma) into the air. The chaff is blown away and the grains of corn, being heavy, fall onto the pile. After a time the wheat and chaff form separate heaps. This is the traditional way that takes a long time and is difficult.

The second way is by using a separating machine. This is made of a fan that can be turned by mechanical means. The faster the wheel turns, the greater the air current produced. They add a sieve to the fan, made of steel wires, that rocks backwards and forwards, as the fan turns. They then begin to fill the sieve with the wheat and chaff mixture. At the same time a villager begins to turn the fan very quickly. The air current produced throws the chaff out, and the rocking of the sieve agitates the grain that falls through the holes in the sieve into a pipe fixed to it, then to the ground behind the machine. They repeat the procedure with the already-winnowed grain with the same machine using a finer sieve, allowing a filtered and cleaner grain to be produced. One machine can complete the winnowing of a whole pile in one or two hours. [13]

The weighing and checking of the tithe portion (see the ‘Local Rule’ sub-heading) takes place during the second stage. Then the peasant takes his portion home, where special stores are constructed. [14] The chaff and stalks that haven’t been threshed properly (those that are hard and haven’t separated) as well as small pieces of chaff (used in making mortar mix) remain on the threshing floor. The villagers take the straw to their barns and carry out another threshing and winnowing of the hard stalks and ears that have remained. [15]

The grain taken home and stored is sieved and the cleanest, largest and ripest are kept for the next year’s sowing.

The preparation of bulghur

Bulghur (buglur or bghlur) is one of those items, like gorgod (cracked wheat), lentils, chick peas and beans which are kept separately by the villager and used in meal preparation. These kinds of staples are known as abrtsu. Bulghur preparation is difficult and takes days to complete. It is made from the kind of wheat known as ashora, from which flour for bread-making is also prepared. First the housewife examines it and, according to the number of family members, determines the amount of wheat to be made into bulghur. Generally speaking each person uses 3 olchags of bulghur a year, in other words 92.1 kg (about 203 lbs). The first part of it preparation is to ‘tray’ it. This work is reserved for the women. They take a quantity of wheat and put it in a wooden tray (depur) with about 75 cm (about 2 feet 6 inches) diameter. They throw the contents up into the air, then catch it, allowing the dust and chaff to fall away, the grain collecting in the middle. Then the peasant woman sorts and cleans it by hand, until every foreign particle has been removed. [16]

Then several large brass tubs half-filled with water are set on lit stoves. After they have heated for a time, each then has about 1-1.5 olchags (30.72-46 kg, 67.6-101 lbs) of the cleaned wheat added. The water is allowed to boil; the contents are stirred with large wooden spoons and the wheat swells and rises to the surface. This is the sign that the contents of the tubs have boiled. Then the boiled wheat is taken up to the flat roof. There it is spread out evenly (meynel) and left for a few days, until it dries in the sun. They then bring it back into the house and repeat the ‘traying’. The wheat is thus completely cleaned. It is then put it into sacks and each sack’s mouth is sewn up with needle and thread. [17]

It is taken in this state to the press (tsitihank), where the work is carried out by men. The work of grinding it starts here. They gradually fill the press table with wheat, pour a little water on it then, using either an ox, buffalo or horse, begin to turn the press roller in a circle. The wheat, under this heavy roller, is separated from its bran. If the bran is well separated from the wheat, then the quality of the bulghur will be high.

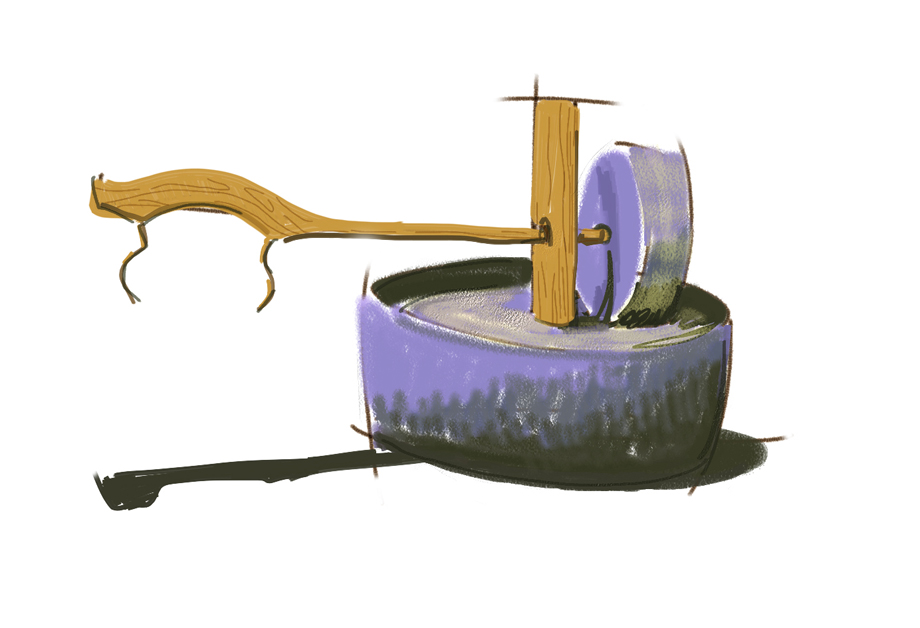

In some villages there are special presses, built near water mills. These are named deng, or ding. Like watermills, these are two-storey huts. There is a wheel made of oak on the lower floor that is turned by the power of the water. Its axle is between 2.5 and 3 metres (7 feet 6 inches and 10 feet) long and 8-10 cm (3 to 4 inches) diameter. A stone grinding wheel is fixed to the axle that turns with it on a secure base. Here too they pour refined wheat onto the table or base, and the bran separates from the wheat itself. [18]

The ground wheat mixed with its bran is once more taken up to the flat roof, where they spread it out (meyel) and left for almost a complete day, until the dampness completely evaporates. Then all the wheat is sieved, separating the bulghur from the bran. This is followed by grinding, generally carried out in the home, using small grinding wheels. From two up to five grinding wheels are set up in the house; the work is carried out by the young men of the family who, in this instance, call in their neighbourhood friends to assist. One of them holds the vertical post set into the top of the upper stone and, pushing it, turns the stone in a circle. At the same time, another person, seated next to him, feeds handfuls of bulghur into the hole in the middle of the upper stone. This is what makes the bulghur into round pieces. The ground bulghur is then given to the women and girls, who sieve it once more. The reason for doing this is to separate the small pieces from the rest. The large pieces are used to make a hot staple food called pilav (yeghints), while the small pieces are for kufta (patties). The ground and separated kinds of bulghurs are put into barrels, whose mouths are well sealed. [19]

They also prepare cracked and ground wheat that are abertsu and are second in importance. These two cereals are made from mandjak wheat, whose individual grains are too hard to use to make bread. The preparation of cracked and ground wheat is not too difficult. The mandjak wheat is first sieved, then laid out (as they do for ordinary wheat) and later ground in the press for a long time. It is ground more easily, bearing in mind that it has not been boiled first. Then it is taken to the flat roof of the house where, after drying, it is winnowed, separating the chaff from the ground wheat. A final act is sieving. To do this two different sieves are used. The first is a coarse one, the second, fine. The result of the first sieving with the coarse sieve is cracked wheat, and the second ground wheat that, in reality, is the crumbs of the former. The people in the northern villages of Palu district call ground wheat gorgod, while those of the southern villages give the name to the crumbs. [20]

- [1] Rev Harutiun Sarkisian (Alevor), Palu: its customs, educational and intellectual state and dialect (in Armenian), published by ‘Sahag-Mesrob’, Cairo, 1932, page 86-87.

- [2] Ibid., page 88.

- [3] Ibid., page 88, 92.

- [4] Ibid., page 88-90.

- [5] Ibid., page 89, 90-91.

- [6] Ibid., page 93.

- [7] Ibid., page 95-96.

- [8] Ibid., page 96-97, 101.

- [9] Ibid., page 97-100.

- [10] Ibid., page 101-102.

- [11] Ibid., page 102-104.

- [12] Ibid., page 104.

- [13] Ibid., page 106-107.

- [14] Ibid., page 109.

- [15] Ibid., page 111-112.

- [16] Ibid., page 112-114.

- [17] Ibid., page 114-115.

- [18] Ibid., page 115-116.

- [19] Ibid., page 117-118.

- [20] Ibid., page 118-119.