Hayni – Trades and Economy

Author: Varouj Tenbelian, 20/08/2021 (Last modified: 20/08/2021) - Translator: Simon Beugekian

This article explores the economy of the town of Hayni and the trades practiced there. The information provided here comes from a book written by Penyamin G. Jamgochian, entitled Hayni, and published in Beirut in 1952; as well as the book Houshartsan Ousoutschabed Penyamin Jamgochiani [Memorial for the Schoolmaster Penyamin Jamgochian], published in 2010 by the alumni of the Sahagian School of Beirut. The article concerns trades practiced in Hayni in the early 20th century, at which time Jamgochian lived in the town.

Hayni was a town with a mixed Armenian-Kurdish population. Over the centuries, these two ethnic groups had established a harmonious relationship. Armenians and Kurds would visit each other, break bread together, and call each other kirva (godfather). They had cultivated mutual trust, which was especially evident in the commercial transactions between them. Jamgochian tells of Kurds arriving in Hayni with 10-20 pack mules or pack horses carrying agricultural products, and immediately heading to the home of this or that Armenian family. They would unpack the animals, tie them in the courtyard, enjoy a meal with the household, and sometimes even spend the night, sleeping on clean beds and enjoying the full hospitality of their kirva. Traveling Armenian merchants were treated in the same manner in the area’s Kurdish villages.

Interestingly, the economy of Hayni had developed in such a way that Armenians and Kurds dominated different fields. Moreover, there was a system of cooperation between craftsmen belonging to the two ethnic groups.

The Kurds were generally landowners or were engaged in agriculture and animal husbandry. They owned most of the land. However, ownership of some large and fertile fields had been transferred to Armenians in lieu of payments of debts. Kurds in the town also owned five or six fabric stores and one cobbler’s stall. This cobbler, according to Penyamin Jamgochian, may have been a Kurdified Armenian [1]. There were also Kurds who were grape farmers, gardeners, mule keepers, or who raised other animals.

Armenians were mostly engaged in grape farming, commerce, and other crafts.

We must note that some occupations were ambulatory by nature. In Hayni, the unwritten rule was that cobblers, pewterers, farriers, and traveling peddlers would spend a portion of the year away from the town, working in nearby Kurdish villages. They would return home around harvest time (depending on the season), laden with various provisions [2].

It was also customary in Hayni for specific families/dynasties to monopolize certain trades and occupations.

Grape Farming/Wine Growing

Hayni’s vineyards produced a rich array of grapes, renowned among which were the mazroum (both white and red), mahser, khrpok, madmad (similar in appearance to cucumbers, elongated and yellow), kurmuz, djunsan, grdan, hasan (ball-shaped and very sweet), and black grapes (used to make raisins and wine) [3]. Aside from grapes, the town’s vineyards/orchards had only almond trees and fig trees (in the form of bushes). The hedgerows consisted of blackthorn shrubs and blackberry bushes. Almost every household had its own vineyard.

The people of Hayni did not sell their grapes, instead keeping them for their own domestic consumption. Sometimes, they bartered grapes with Kurdish women from distant villages in exchange for cereal, lentils, chickpeas, or flour.

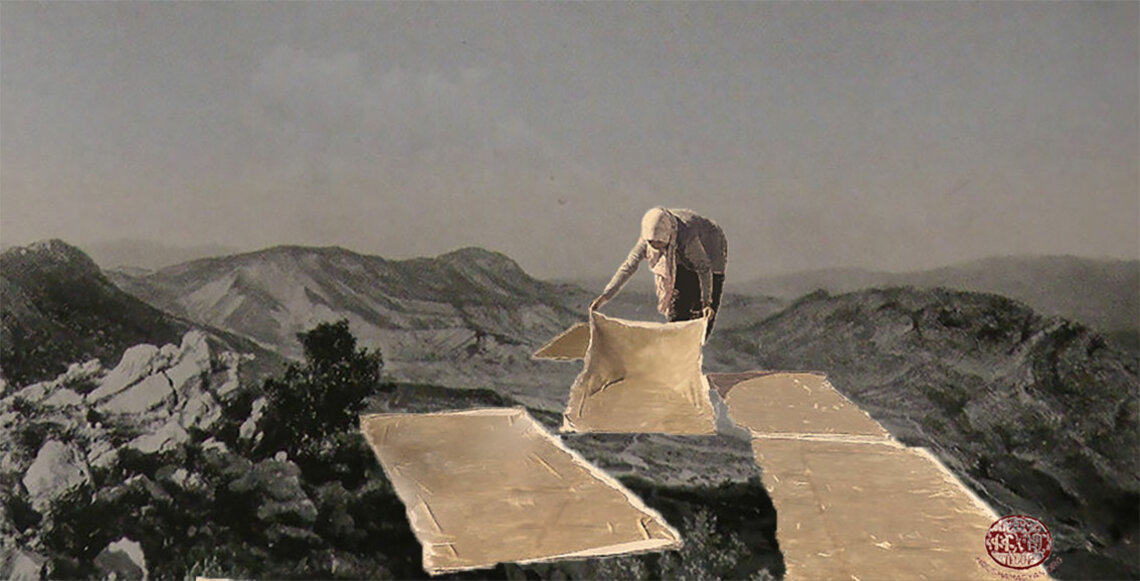

At harvest time, the entire population of the town would pour into the vineyards, each household into its own. Households lacking vineyards were a rarity in Hayni. Jamgochian recalls that the picked grapes would be transported, in a type of special basket called ktots, to special pools made of clay (mahsere), built outside of the vineyard huts. Once a mahsere was filled to the brim with grapes, youth would jump in, unshod, and stomp the grapes. The grape juice (shire) would be drained, then flow out of an outlet at the bottom of the pool and into cylindrical, clay jugs (karsa or tashkhouran). These jugs would be emptied into large tubs (tashens). The juice would be poured into vats, which would be heated on a low flame. It required special expertise to prepare malez (thickened grape juice) – a skill that the ladies of Hayni had mastered. They knew just how long to boil the grape juice, which would determine the taste of the bastegh (grape leather; locally known as latkash), rodjig (grape sudjuk, locally known as sharots), and kesme (gdron). The bastegh of Hayni was well-known for its thinness and sweetness [4].

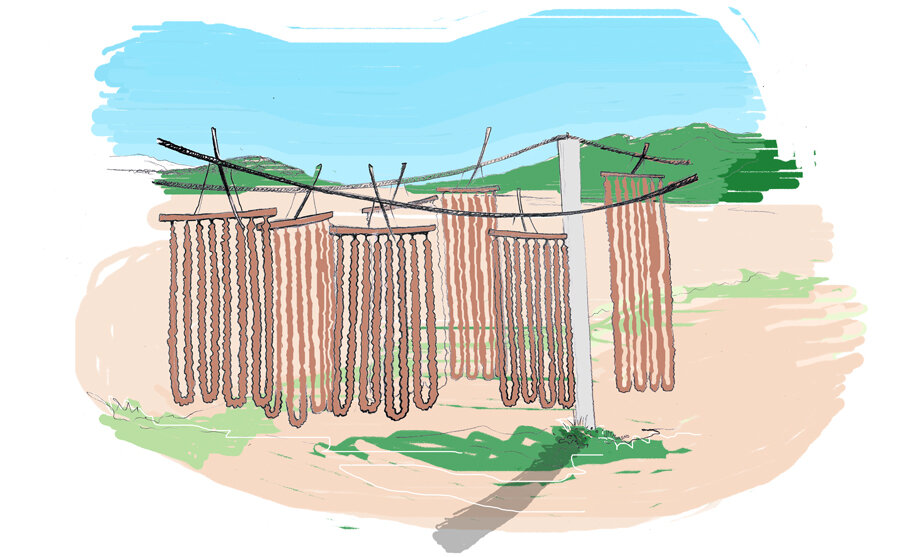

Jamgochian emphasizes that the preparation of rodjig/sudjuk/sharots required a certain talent. Poorly made malez would not stick to any walnuts or almonds added to it. To make rodjig, walnuts and almonds would be connected by a strong thread and then immersed in malez. The resulting garlands would be hung, and once dry, would be dipped in malez again. Rodjig and other grape products were preserved in special jugs [5].

To preserve grapes during the winter, the locals wrapped them and then hung them. This process was called deyle. The grapes could thus be preserved until Easter. Aside from daily consumption, grapes were also used to make confectionaries and wine. Each home would make its own, and throughout the winter, would enjoy its own sweets and indulge in its own wine, sharing it with neighbors and friends. There were also locals who distilled more potent spirits from their leftover grapes or with raisins [6].

Hayni’s vineyards were generally not irrigated.

The people of Hayni had developed a unique method of preserving vines. On the eve of summer, around the time of Lent, they would dig the soil under the vine and prune the boughs with a hooked knife (kshoush or hodots). They would then prop up the vines above the ground with wooden stakes, which Jamchogian calls sarpinas. In this way, a hollow was created under each vine. Moreover, broken vine boughs were piled up and allowed to dry up, then braided together to make thin walls. These walls were used to create makeshift open-air rooms on the locals’ roofs during the summers (called erzel or arzel, according to Jamgochian), where they would sleep on hot nights. The beds/mats were not left in these makeshift rooms during the day [7].

Carpentry

The carpenters of Hayni usually worked with the wood of mulberry trees. They used simple tools, including the saw, adze, chisel, rende (planer), chaghap (a tool shaped like a violin bow, used to spin a piece of wood while the carpenter rounded it with a chisel), erzahan (a long planer), and rasp. Hayni’s carpenters made elbes (wooden pails), spoons, tatigs (scratchers), cheleps, dolchas (large ladles), kharkhaps (clogs), sieves, trays, chisels, keys, and agricultural tools [8].

Well-known families and craftsmen engaged in carpentry in Hayni included Koudoghenk, Nadjarenk, Isgoyenk, Terzinounenoyenk, Der Avedisianenk, Kousherants Sarkis, Tupo, One, Malkaghanents Garabid, Boghosents Boubo, Topal Nanoyenk, and Der Khachadourenk [9].

Copper smithing

Copper smithing was a highly developed craft in Hayni. The locals procured raw copper from the Bakhur Maden area, and master craftsmen shaped it into pans, tubs, kettles, and various kitchen vessels, including the brgish (a concave tray without a rim and with its ends raised) and the sini (a round, flat tray). Sinis and brgishes were often in lieu of tables. Many of the products crafted by Hayni’s copper smiths were used as far afield as Diyarbakir/Dikranagerd, Bitlis/Paghesh, and Erzurum/Garin.

According to Jamgochian, there were 76 to 176 coppersmiths in Hayni. Well-known families and craftsmen engaged in this occupation included Onogourents Manoyenk, Chlhents Khachoyenk, and Bsgsnets Toumasenk [10].

Blacksmithing

It is unclear how many blacksmiths were active in Hayni. In the center of their workshops, they would have a circular workbench, made of earth and stone, standing at a height of 70-80 centimeters above the ground. This workbench would also serve as a furnace.

In the rear of the shop would be a pair of large bellows, which an apprentice would operate to feed air to the fire. The bellows were connected to the pit that served as the blacksmith’s forge, filled with coal and in which the metal would be heated. Beside the forge was another pit, filled with water, used to cool down the metal. Among the many necessary tools of the trade was the anvil, usually placed before the forge, beside which would be arranged the agish (a flat fan used to stoke the fire), the koushta (a piece of hooked metal), hammers of various sizes, tongs, and other implements.

The town’s master blacksmith would make all the metal tools and metal parts of non-metal tools needed by the townspeople.

Well-known families engaged in blacksmithing in Hayni included the Malkazanenk (Sdumbolchonk), Gopoyenk, Kavroyenk, and Koutsoyenk [11].

Weapon smithing

Weapon smithing was well-developed in Hayni, specifically to fulfill the demand from the Kurds. For this reason, Hayni’s Armenian weaponsmiths were the local Kurds’ closest friends.

Hayni’s weaponsmiths used locally crafted tools to make cheykhanas, khanchers (daggers), and some of the most delicate parts found on European weapons, whether made of wood, bone, or metal.

Well-known local weaponsmiths included Sdumbolchonts Krikor, Srabenk, Atoyenk, and Sheikhoboghosenk [12].

Farriers (Nalbands)

Some of the local farriers worked in town throughout the year, while others spent the spring and summer traveling to nearby Kurdish villages where their services were in demand.

Well-known local farriers included Bozoyenk, Mkayelenk, Nalbandenk, and Gouloyents Korko [13].

Cobblery

This was one of the most common occupations in Hayni. Cobblers would spend several months every year working in the area’s Kurdish villages. Almost every family in Hayni had at least one cobbler among its members. Many of these cobblers were specialized in repairing old shoes and were called pinechi.

In Hayni, cobblers had no access to processed leather, hides, or ready-made lasts. All leather-related work, from the desalting of raw leather to its final treatment, was performed by the local cobblers.

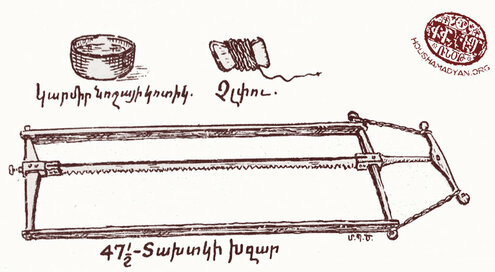

The ground floor of each cobbler’s home would feature an above-ground pool, called silag. After being immersed in the silag, the raw leather would be taken to the local dabakhana (tannery), which, according to Jamgochian, was an old building that had been purchased by the town’s cobblers from Mahmoud Agha. As such, it was the collective property of all of Hayni’s cobblers. The water supply needed for the tannery was provided by the Enkebir Pond. A stream originating from the pond flowed right beside the building. The leather would be immersed in the water for seven full days, after which it would be removed and placed on a plank of wood about one to two meters in length. Then, the cobblers would use a bow-shaped knife, with a handle on each side, to scrape the leather. The clean and softened leather would be taken back home and immersed in the silag again [14].

Dabagh (also tapagh) was a substance prepared by tanners/cobblers to treat leather. It consisted of kghtor (gallnut), gjuk (onion roots), sumac bush, and rotted round kakol (we were not able to identify this substance). The cobbler would rub the dabagh onto the clean leather to strengthen it. Then, the exterior of the leather would be painted red or black. The dyes were obtained from gypsum.

The final product, the treated leather, would be taken to the shop to be shaped into slippers (closed-toed, with a tail, and with no heel), kaloshes (heeled shoes), and other leather goods (saddles, bridles, reins, etc.).

One of the tools used by Hayni cobblers was the goudj (or godj). This was part of a tree trunk, to which were affixed three or four models of feet. The goudj served as the cobbler’s workbench. There was also the msap, which was a hammer with a rounded head and a flat peen, and which was usually yellow in color. Other tools of the trade included the awl, the needle, the gaz (a knife with a rounded tip), the masat (used to sharpen knives), and hesan (stone/anvil). There was also the endaza (or undaza), the shoe mold. Alongside these specialized tools, cobblers also used wooden tools of different sizes and shapes, each of which had its own name, which Jamgochian, as he regretfully states in his book, was not able to recall. Many of these were used to enlarge or stretch out different parts of the shoe.

Well-known local cobblers included Kergvorenk, Shnourenk, Khchenk, Jamgochenk, Fermanents Mgro, Arsouzenk, Manoyenk, Shehreshents Ohan, Melkon, and Mkhs Arakelents Ohanes [15].

Pewterers

Pewter-craft was another popular occupation in Hayni, with about 60 households engaged in it. In the local vernacular, a pewterer was called a kalaychi. These craftsmen lived an interesting life, as their work was usually ambulatory. Kalaychis traveled from village to village and from town to town to practice their trade. Specifically, they would set out on the first day of Lent, and nobody knew when they would return. Usually, they would be back home in the autumn. Sometimes they would travel south, as far as Palestine; and sometimes north, as far as Garin (Erzurum).

The tools of this trade were simple: a pair of bellows, a gyaz (tongs), some pewter, various small implements, and teghrounk (solutions/chemicals) [16].

The kalaychis of Hayni had their own secret lingo, which had probably developed as a result of their constant travels (sometimes to strange and new places). Here are some examples of the expressions that they used:

- Dzagh gdrel [slice a cake]: Eat bread.

- Kelou khod [wolf’s grass]: Ghavourma (a meat dish).

- Lat kash [pulled cloth]: Bastegh (grape leather).

- Yergat gu dzezde [he/she is beating iron]: He/she understands it.

- Kabu pir: Bring over the plate.

- Yergar angadj [long-ear]: Donkey.

- Yergar tatig [long-arm]: Thief.

- Anosgor ige [a boneless one has come]: There are lice here.

- Dzkhakhod ige [tobacco has come]: There’s a Kurd here.

- Gatil [drops]: Dubus, roub (grape molasses).

- Vosbu karoud e [there are rocks in the lentil]: A stranger is among us.

- Yerginku tonoud e: An enemy is among us.

- Yersoun ige: A Turk is among us; also Ramadan.

- Hisoun e: He/she is Armenian; also Lent.

- Khoshour mjegh [large fly]: Turk.

Well-known families engaged in pewtering in Hayni included Djouharenk, Kaplanenk, Bsgenk, and Bouboush Kevoyenk [17].

Weaving

One or two members of each of the approximately 100 Armenian families in Hayni were engaged in this occupation. In later years, when the trade in fabrics became lucrative, many families abandoned the craft of weaving in favor of becoming tradesmen in the industry.

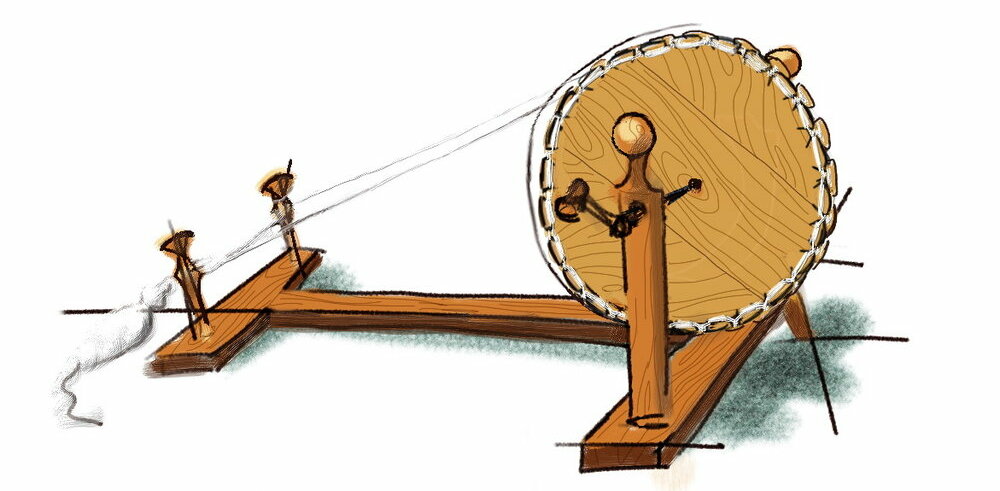

The fabric weavers of Hayni would dedicate a room on the ground floor of their homes to their trade. In one corner of the room, they would dig a knee-deep pit about a meter long and about 50 centimeters wide. At one end of the pit, they would fix a cylinder into the ground, resting on two props on either side. This cylinder, a crucial device in the weaving process, was called the sarmin (cloth beam). On both sides of the pit, pointing towards the center, would be two additional braces that would support the two ends of the comb. A circular post of about 20-25 centimeters in length would be placed on two other props at a distance of about 3 meters from the pit [18].

In his book, Jamgochian mentions various tools and devices used by the weavers of Hayni, as well as other terms, some in the local dialect, that were associated with this occupation.

Each household’s bride and her mother-in-law played an important role in the process of weaving. They had the duty of cleaning the cotton and shaping it into “twigs” that measured about 20-30 centimeters in length (badrouka). These badroukas would then be spun using a treadle [19].

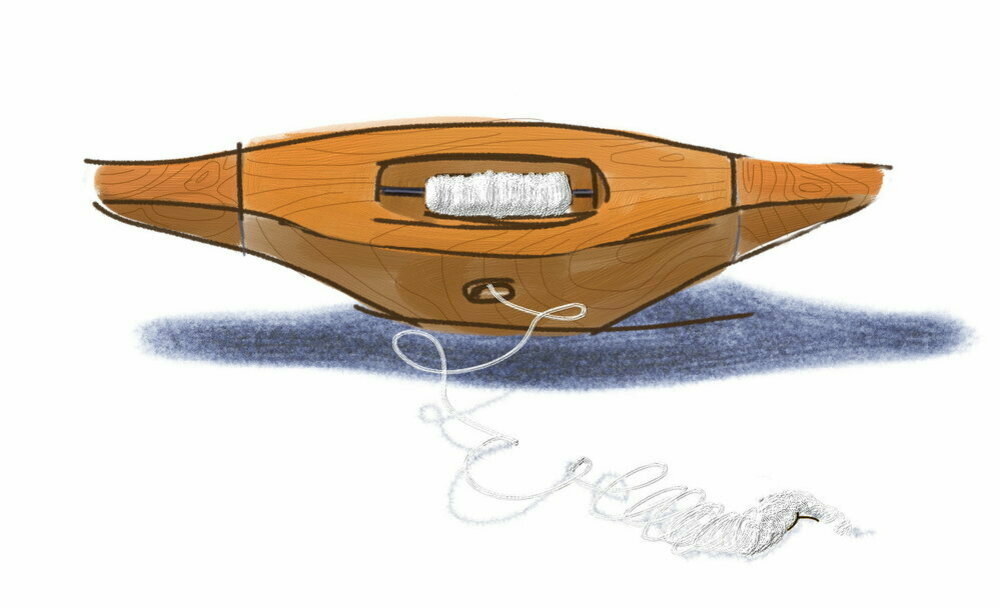

The spun thread would be looped into a device with four to six rods, called a nazoug. With this device, weavers made strands of fabric that were the width of a wrist, called manadz. In order to make sure the strands held together, the manadz was dipped in shrez (an adhesive solution). Then, the household’s women (usually) would loop these strands into another device like a nazoug, but larger, which was called a garjar (garj-gaj; skeiner), and would use a treadle to prepare the tardags (reed pipes of 5-10 centimeters in length; spindles). Once ready for use, the tardags were called masouras (bobbins). The weaver would load the desired number of masouras onto the sderch or destidjagh. This was a device that looked like a sewing shuttle, featuring 24-36 metal spikes on which the masouras could be affixed [20].

The next step was to prepare the hevandz, which was the cloth to be weaved. Jamgochian described this process: about 20-30 meters away from the home, two or four long stakes were planted in the ground, about 2-3 meters from each other. These stakes were called stits. Then, a number of tardags, corresponding to the desired width of the fabric, would be fixed onto the “deste jagh.” Jamgochian writes: “They would connect the thread from all the tardags and tie them to the first stake, then proceed forward, and each time they reached a stake, they would go around it, from alternate sides. By performing this operation, they would prepare the cloth of the desired length and of the desired quantity. This was the hevandz [21].

Continuing to describe the work of the weavers, Jamgochian mentions that they would expertly roll the hevandz into a ball, which would then be hung from a corner of the ceiling above the pit loom. The thread would pass over a solid bar also suspended from the ceiling, then over another bar affixed to the ground at a distance of two-three meters from the pit, having been split into individual strands. Then, each of these strands would pass through loops of solid strings, two sets of which would be fastened to two separate bars. These bars were connected to two pedals at the bottom of the pit, allowing the weaver to split the warp into strands and feed them through the shuttle. The looped strands would pass through a comb and were fastened to the sarmin. The comb’s teeth would consist of thin strands of reed, 1-2 millimeters wide and 10-12 centimeters long [22].

After completing all necessary preparations, the weaver would sit with his feet in the pit, and using the wooden pedals, begin weaving the fabric. He would rapidly move the shuttle from side to side, and with each pass, would strike the woven fabric with the def to make sure that the threads were fastened together. The def was a plank of wood suspended from the ceiling. In Arabic-Turkish, def means steering wheel. The weavers were also responsible for dyeing the fabric. Their dyes included red alezar, khlekar (white like soap dust), gypsum, alum, and various other substances (solutions and chemicals).

Well-known local families and craftsmen engaged in fabric weaving were the Khachadourians, Topchounk, Srabenk, Dubsenk, Khalf Arakelenk, Aghasenk, Djaoualisenk, Kel Eghsoyenk, Eghoyenk, Balbalenk, Khalf Manougank, Der Manouelenk, and Manasdourenk.

Khzardjis (Sawyers)

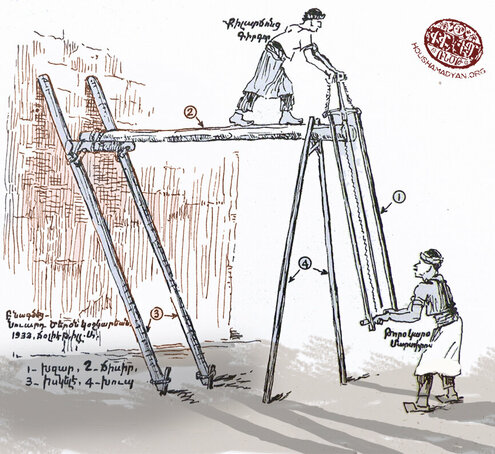

These were craftsmen who cut and sawed tree trunks into long planks of wood. Sawyers in Hayni would fasten four logs in the shape of an X and use this as a base on which they would position another log four-five meters in length. The lumber to be sawn would be placed on top of this fifth log. The sawyers would use red dye to mark the wood to ensure they cut it into pieces of the desired size. One of the sawyers would climb on top of the logs, a colleague would stay below, and the two of them would operate a long saw together [23].

Other Trades

Less-popular occupations and trades that were practiced in Hayni included:

- Painters: Local painter included Zoroyents Korko, Choloyents Garo, Aboyents Manoug, Simoyents Garabed, ad Boyadji Simonenk.

- Cotton de-seeders: Local cotton de-seeders included Ghougoyents Arakil, Choughougants Hagop, and Ohan.

- Basmadjis (artisans who made decorative curtains, table sheets, and cases): Local basmadjis included Badmachonk, Chalumenk, Khach Khatounents Mroyenk, Tayrenk, Chalughenk, and Eghoyenk.

- Saddlers: Local saddlers included Chalumenk and Choulchi Bghdoyenk.

- Mill builders: Local mill builders included Anteyenk, Isroyenk, and Der Movsesenk.

- Butchers: Local butchers included Akrenk, Kesenk, Fermanents Ferman, Tanonts Ohan, Ghougas, and Lalents Garen.

- Midwives: Locally known as tigmar or ptogh/pattogh. Among the well-known local midwives were Mcho Mro (Anoush) and Mahobents Saro.

- Hayni was also home to jewelers, barbers, saddlers, felters, and bakers. There were also those whose primary occupation was grinding wheat and dzedzadz (cracked wheat). They were called dingdjis [24].

- [1] Penyamin G. Jamgochian, Hayni, Beirut, Lebanon, 1952, p. 21.

- [2] Houshartsan Ousoutschabed Penyamin Jamgochiani [Memorial for the Schoolmaster Penyamin Jamgochian], published by the alumni of the Sahagian School of Beirut, Beirut, 2010, p. 35.

- [3] Jamgochian, Hayni, p. 22.

- [4] Houshartsan Ousoutschabed Penyamin Jamgochiani, p. 39.

- [5] Ibid.

- [6] Jamgochian, Hayni, p. 22.

- [7] Ibid.

- [8] Ibid., p. 23.

- [9] Ibid.

- [10] Ibid.

- [11] Ibid.

- [12] Ibid., p. 24.

- [13] Ibid.

- [14] Ibid.

- [15] Ibid., p. 25.

- [16] Ibid.

- [17] Ibid.

- [18] Ibid., p. 26.

- [19] Ibid.

- [20] Ibid.

- [21] Ibid.

- [22] Ibid., p. 27.

- [23] Houshartsan Ousoutschabed Penyamin Jamgochiani, p. 31.

- [24] Jamgochian, Hayni, pp. 27-28.